The temperature of the material transported by the TD75 belt conveyor is below 50 °C. The ambient temperature is +40 ° C ~ -25 ° C. If appropriate protective measures are taken, it can also be applied to special requirements, such as explosion-proof, waterproof, anti-corrosion and heat-resistant, and plug-resistant.

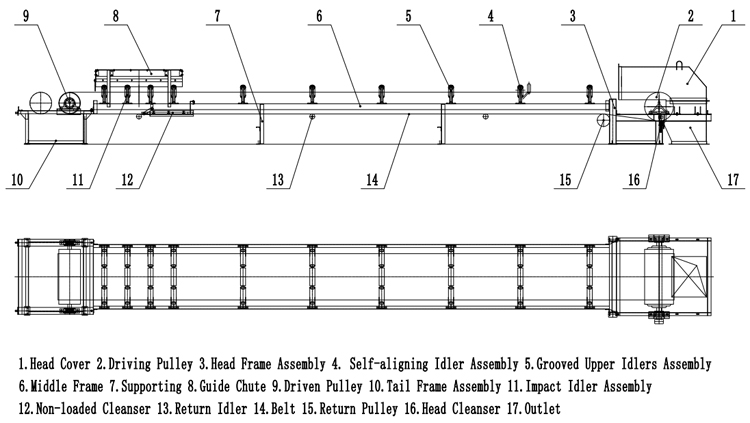

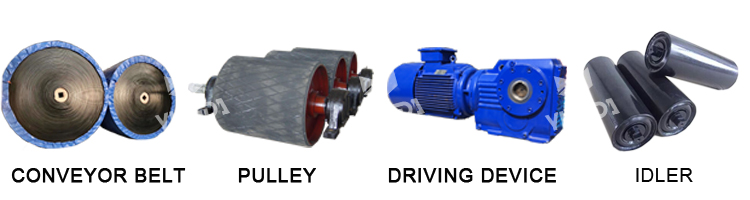

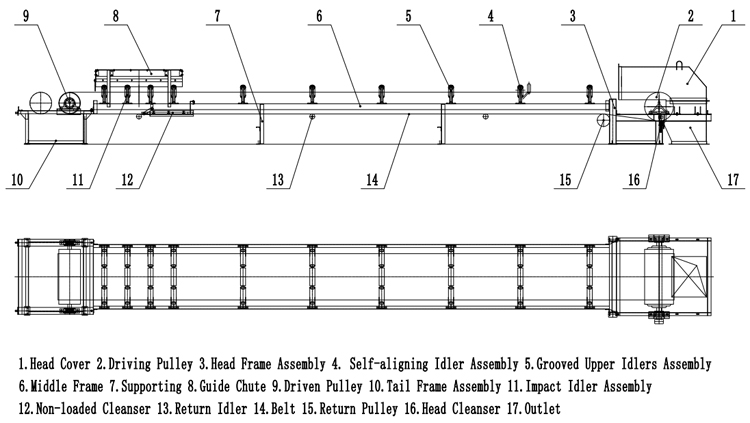

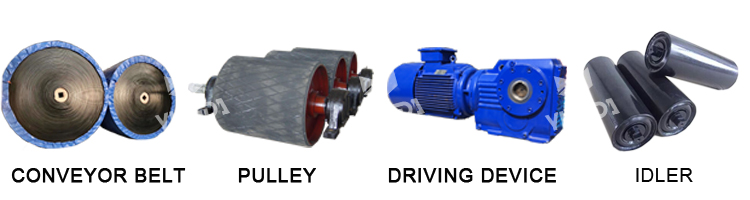

Drive part: It consists of the motor on the base welded by the steel plate --> high speed coupling --> reducer --> reduction coupling. According to the layout requirements: the drive unit is available in left and right mounts. In addition, the company is equipped with an oil-cooled electric drum with a power of 1.5KW to 13KW and a speed of 0.80, 1.0, 1.25.

Rolling part: two types of sub-drive roller and reversing roller.

Roller parts: slotted, parallel, self-aligning and cushioning rollers.

Cleaning section: Split spring cleaner and empty section cleaner.

Unloading part: divided into fixed plow type unloader and electric unloader.

Finally, the belt drive cannot be disconnected from the rear stage of the inverter. If it is necessary to determine the maintenance, it must be stopped when the inverter operation is stopped. Otherwise, the inverter may be damaged.

The belt conveyor stops running. Press the stop button to stop the total power after the system is completely stopped.

Products

Products

Inquiry

Inquiry

WhatsApp

WhatsApp

Top

Top