Description:

Screw conveyor is spiral bulk material transportation system that convey raw ingredients to and from processing areas that are on different levels of a facility. Screw conveyor can transport materials horizontally, also it can slanted at different angles to economically elevate and convey materials up and down floors. It require ample space and an increased amount of power to lift the material, depending on the steepness of the angle.

Two Types:

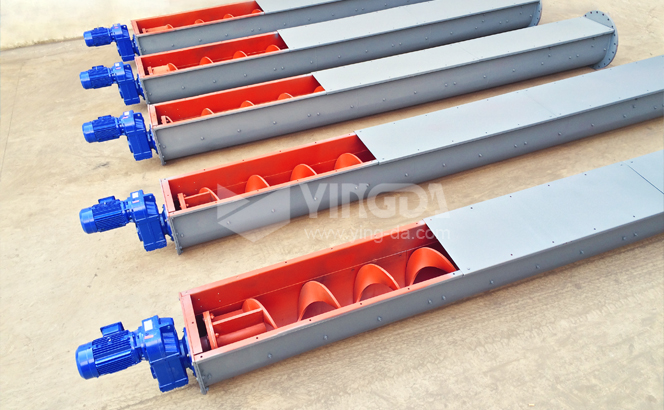

1.1 Shaft screw conveyor: LS series ( Tube & U/ trough shape )

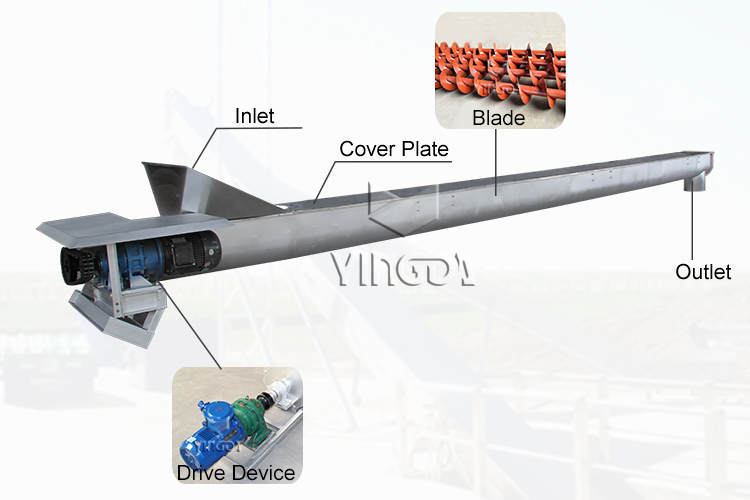

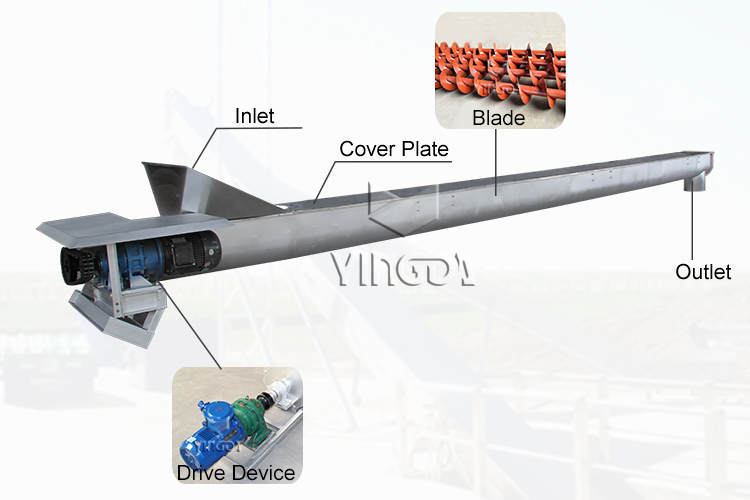

Screw Conveyor is a continuous conveying equipment which used to transport powder, granular and dry bulk materials. It consists of bearing seat, screw blade, screw shaft, hang bearing, conveyor casing and driven device,etc.Single or combination of multiple screw equipment can be used to integrate with each other to meet particular on-site requirements. It has trough type tube with multiple inlets and outlets, which also has inclination angle of maximum 20°. The rotation of the blade initiated by the motor, then material transferred along the spiral to the outlets.

1.2 Advantages

1. With cover, whole sealing structure, without pollution to the environment.

2. Conveyor length can be customized according to your need.

3. Trough screw conveyor machine can be multiple inlets and outlets.

4. Reducer motor brand can be domestic or imported: Tailong, SEW, Siemens etc.

5. Easy to disassemble into several sections, save space during transportation.

2.1 Shaftless screw conveyor: WLS series ( U/ trough shape )

Screw conveyor offers highly versatile and numerous solutions for cement feeding and conveying in concrete batching plants, which usually consists of a tube containing rotating helical screw blade coiled around a shaft, driven at one end and held at the other. The main parts also include inlet and outlet chutes and driving device.In addition,cement screw conveyor also widely used for granular and powdery materials at an inclination in many industries, such as concrete mixing station, bulk material transit storage, etc.

2.2 Advantages

1. Adopts continuous spiral blade made of high strength wear-resistant steel with smooth surface,which ensures the uniformity and stability of conveying material, so as to ensure the repeatability of the material measurement.

2. The continuous spiral blade is processed with cold rolled surface hardening treatment, hardness and wear resistance are twice higher than ordinary blade, the hardness of outer edge is up to HB240.

3. Front and rear screw blade adopt sparse and close screw pitch,which can prevent plugging effectively.Meanwhile,the high precision making blase can ensure the material fully filled with pipe casing.

4. Screw shaft with a certain interval are arranged with intermediate hanging bearings,which makes the front and rear blade jointed break interval smaller,and maximize the material passing flow section,thus material flow is smooth and unimpeded.

5. Simple structure,easy operation, low power consumption,flexible layout arrangement.

6. Small screw diameter with impact structure, high rotation speed which maintains large capacity.

7. Total enclosed structure,no pollution to environment,working environment are improved.

Application:

The screw conveyor is widely used for conveying powder, granule, small block materials and sludge etc.

Manufacture process:

Products

Products

Inquiry

Inquiry

WhatsApp

WhatsApp

Top

Top