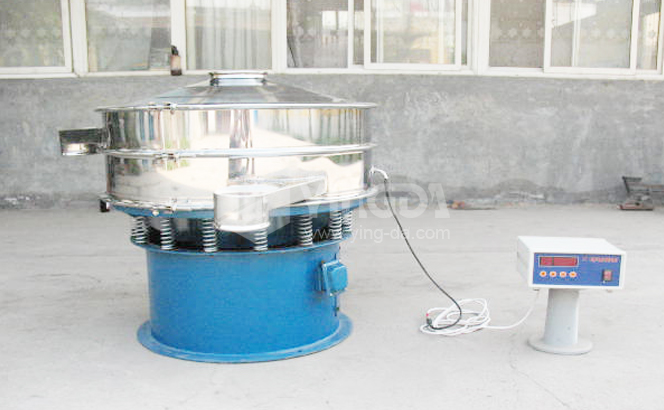

Working principle:

Stainless steel rotary vibration screen, also known as rotary vibration screen, with vertical motor excitation source, the motor installed at both ends of the eccentric weight hammer.The basic principle of Stainless steel rotary vibration screen is through the two ends of the motor installed the weight hammer (unbalanced weight hammer), will change the motor for horizontal, vertical, inclined three dimensional motion, and then the movement passed to the net surface.Changing the phase angle of the hammer at both ends of the motor can change the direction of movement of the material.

Advantages:

1. Small size, light weight, saving space. The direction of the discharge port can be adjusted, coarse, fine material automatically discharged.

2. Screen mesh is not blocked, the powder is not flying, the smallest screen can be up to 500 mesh (28 microns), the smallest filter up to 5 microns.

3. Stainless steel rotary vibration screen with unique grid design, long-term use of screen, easy to change screen mesh, only 3-5 minutes, simple operation, easy to clean.

4. No mechanical action, easy maintenance, can be single or multi-layer use, contact part of the material is made of stainless steel (except for medical use).

Applications:

1. Chemical industry: resin powder, paint, washing powder, fine powder, paint, soda ash, lemon powder, rubber, plastic and so on.

2. Abrasive, ceramic industry: alumina, quartz sand, mud, spray soil particles.

3. Food industry: sugar, salt, alkali, monosodium glutamate, milk powder, soy milk, yeast, fruit juice, soy sauce, vinegar and so on.

4. Paper industry: coating coatings, white mud, black and white liquid, waste liquid, paper liquid, wastewater recovery.

5. Metallurgical industry: titanium oxide, zinc oxide, electromagnetic materials, metal powder, electrode powder.

6. Pharmaceutical industry: medicine powder, liquid medicine, medicine and other particles.

7. Environmental protection: waste, manure, waste oil, food waste water, wastewater processing.

Products

Products

Inquiry

Inquiry

WhatsApp

WhatsApp

Top

Top