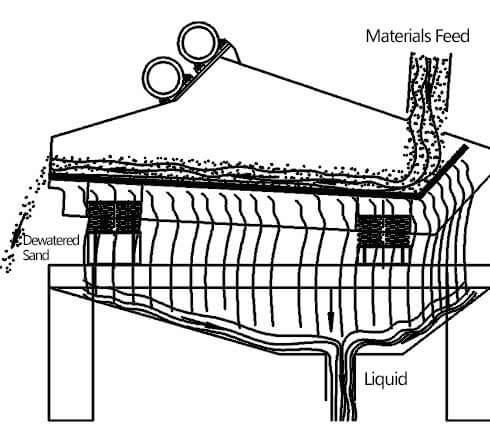

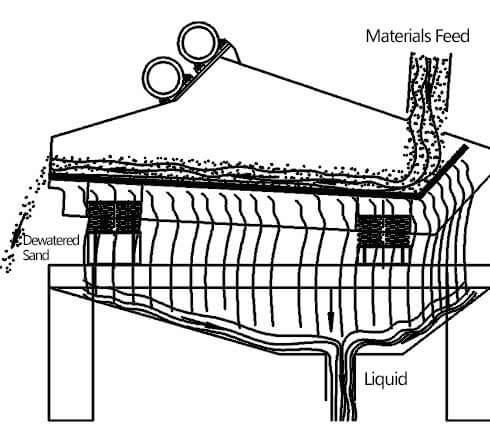

Dewatering vibrating screen adopt dual-electrode self-synchronization technology, universal eccentric block, adjustable amplitude vibrator.

The machine is combined mainly by the screen box, exciter, support system and motor.

The two mutually independent vibrators are respectively driven by the tape coupling to do synchronous reverse operation.

The centrifugal force generated by two eccentric masses is superposed along the vibration direction and reversely counteracted, thereby forming a single vibration force along the vibration direction, making the screen box reciprocating linear motion.

![3MW%C]@W0J{I[2]0L}V8L1U.png 3MW%C]@W0J{I[2]0L}V8L1U.png](/upload/201903/16/201903161805347750.png)

Dewatering screen is produced to solve the above situation that washed sand is too wet. So it is mainly used to dewater sand and fine gravels (typically 0.074-10mm) prior to stockpiling. Depending on the gradation of product to be produced, dewatering screen will typically produce a final product with water content as low as 8%, which is dripless.

Dewatering screen is a common tool, which can not only used in sand processing plant, also can used in mine, ores, clay, slurry, concrete mixing plant, etc. And the feed to dewatering screen can come from a variety of sources, include material washing machine, cyclones, density classifiers, and even directly from classifying tanks.

![3MW%C]@W0J{I[2]0L}V8L1U.png 3MW%C]@W0J{I[2]0L}V8L1U.png](/upload/201903/16/201903161805347750.png)

Products

Products

Inquiry

Inquiry

WhatsApp

WhatsApp

Top

Top