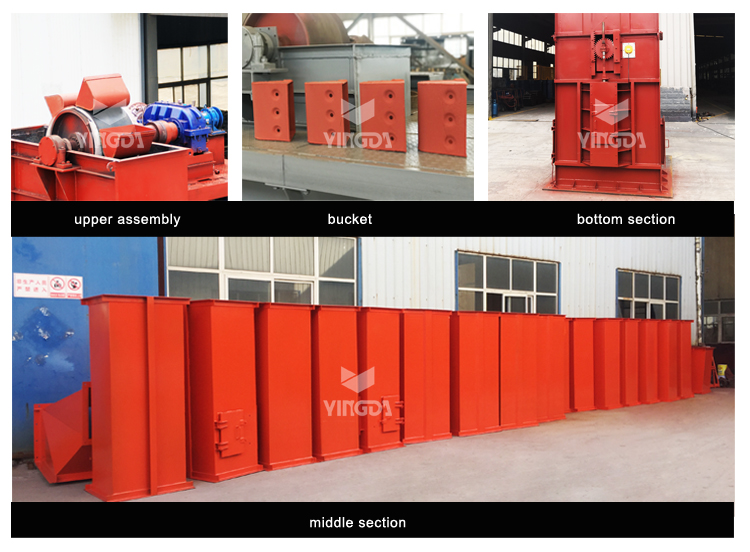

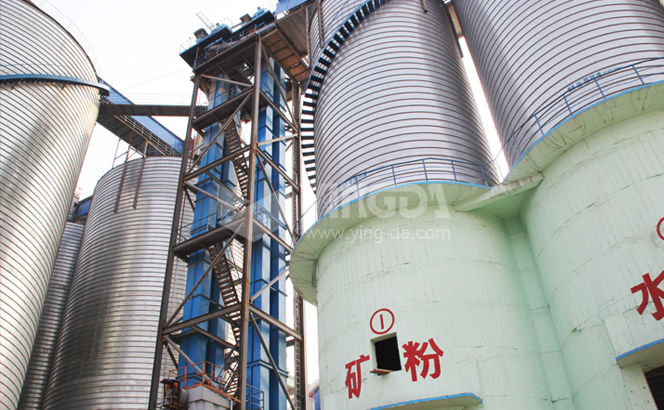

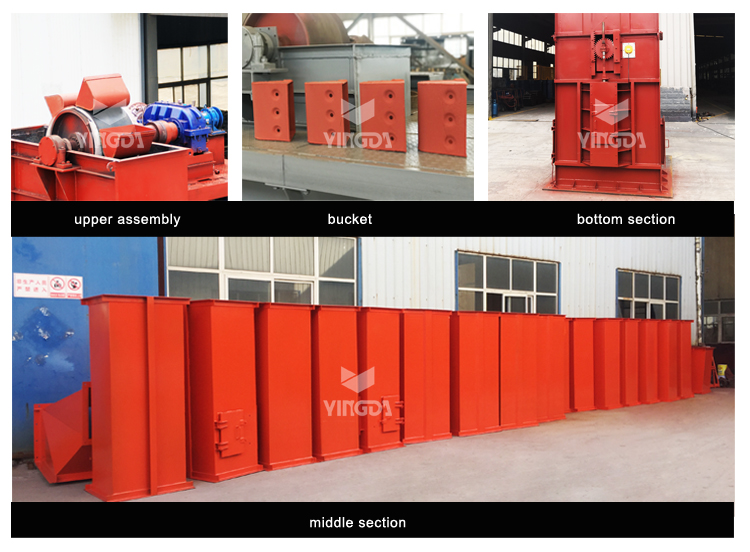

Overview

TGD wire belt bucket elevator is a new-generation product developed by our company through the combination of learning from new foreign technology and domestic production and using practice. The product has the characteristics of large transportation volume, large hoisting height, small volume, low power consumption, stable and reliable operation, long service life, etc. It is suitable for the vertical hoisting of dry, bulk, powdery materials or materials of small granule. It is widely used in the hoisting system of bulk materials in building materials, metallurgy, chemical industry, food, electric power and other industries. In terms of kiln feed into kiln tail, raw material into the homogenization silo, and cement put in storage in the new dry process cement plant, it is an ideal piece of alternative equipment for foreign products of the same specification.

Operating Principle

The high-strength steel wire core rubber belt is used for the drag gear of the TGD bucket elevator, which can overcome the dynamic load generated by the chain meshing drive. It is lighter than the chain, works smoothly, and can achieve higher productivity with faster movement speed. Under the same production conditions, due to the high working speed and light self-weight of the rubber belt, it can reduce the linear load of material and drag gear, thus reducing the size and weight of the complete elevator. At the same time, due to the fact that the rubber belt is well elastic and flexible, it has a damping effect when loading into the hopper. The high-strength steel wire core rubber belt can greatly improve the hoisting height and conveying capacity of the elevator. Therefore, the product has a good development prospect.

Performance Features

1.The hoisting height is large, and it can be as high as 120m with a single elevator.

2. The conveying capacity is high, and its maximum can reach 1100m3/h.

3. The temperature of material can reach 120℃.

4. The hoppers are arranged closely; continuous feeding and discharging.

5. The service life is long, the operational reliability is good, and the failure-free time can exceed 30,000 hours.

6. The power consumption is low, and the energy consumption saving is more than 30% compared with the common elevator, and the cost to use is low.

7. The operation and maintenance are convenient, and there are little vulnerable parts, and the maintenance costs are more than 80% less than that for the common bucket elevator.

8. High-precision structure, high strength and nice appearance.

Products

Products

Inquiry

Inquiry

WhatsApp

WhatsApp

Top

Top