Performance Features | Detailed Specification |

| The series is of elevators with similar structure size and the largest conveying capacity among similar domestic elevators with conveying capacity of 70-2000m3 /h. |

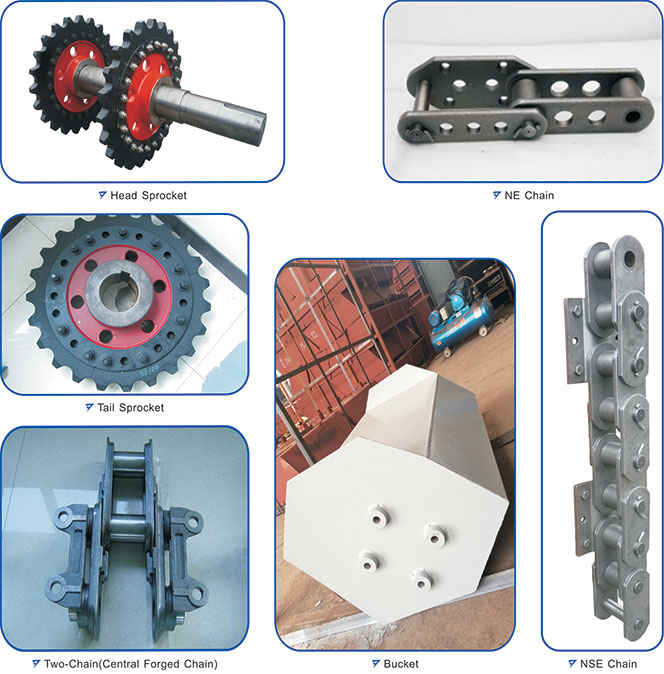

| Subject to flow- through feeding, induced unloading, and intensive layout of hopper with large capacity. There is no back feeding or material excavation at the time of elevating materials, thus there is a little reactive power. It saves 30% power than ring chain bucket elevator. |

| Elevator is subject to flow-through feeding. It is unnecessary to excavate materials with hopper. Avoid any squeeze or collision phenomenon between materials. A little sprinkle at the time of feeding, elevating and unloading is guaranteed in design of the elevator, which reduces mechanical wear. High strength and wear resistant conveying chain is used on Board chain, which greatly prolong service life of chain and bucket. In normal cases, service life of conveying chain are more than 3 years. |

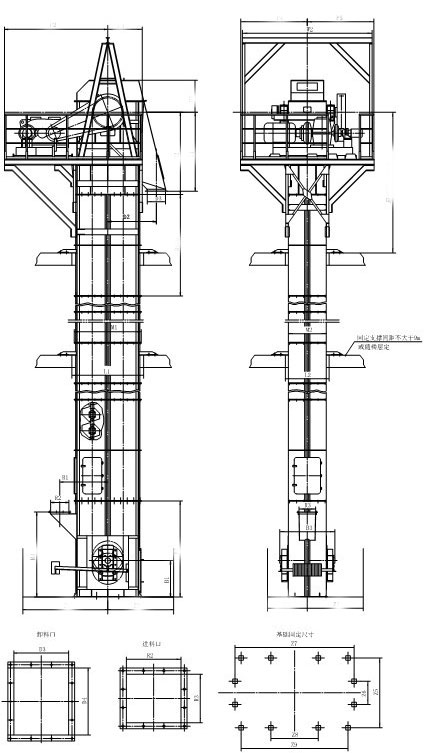

| The series of elevator has no hopper for material excavation, which is stably operated and subject high intensity board chain, thus it can reach higher lifting height and can be lifted to be no more than 55m under rated conveying capacity. |

| The kind of elevators has a few requirements for categories and features of materials, which can be used to lifting powdery and granular materials as well as materials with high abrasiveness and temperature of no less than 200℃. |

| Advanced design principles and machining method ensures the reliable operation of entire conveyor, easy operation and convenient maintenance, and a few vulnerable parts. Moreover, mean time to failure is more than 20,000 hours. |

High Precision | The casing has high rigidity and beautiful appearance after being subject to edge-fold, middle belling, and welding. |

| Low environmental pollution |

| It has low cost of use due to energy conservation and less maintenance. |

Products

Products

Inquiry

Inquiry

WhatsApp

WhatsApp

Top

Top