BELT CONVEYOR VIDEO

BELT CONVEYOR DESCRIPTION

Belt Conveyor is a kind of conveying machine which transport bulk materials and unit loads from one place to another place continuously.

It can be setted both horizontally and sloping. Belt conveyor machine consist of conveyor frame, conveyor belt, conveyor pulley, conveyor rollers, tension devices, driving unit and other components etc.

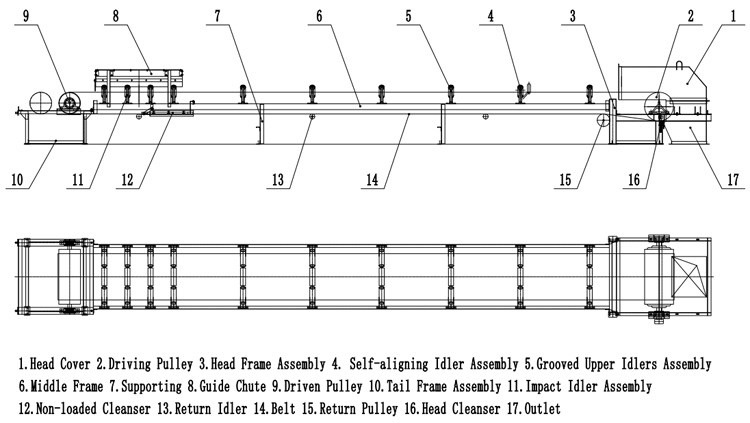

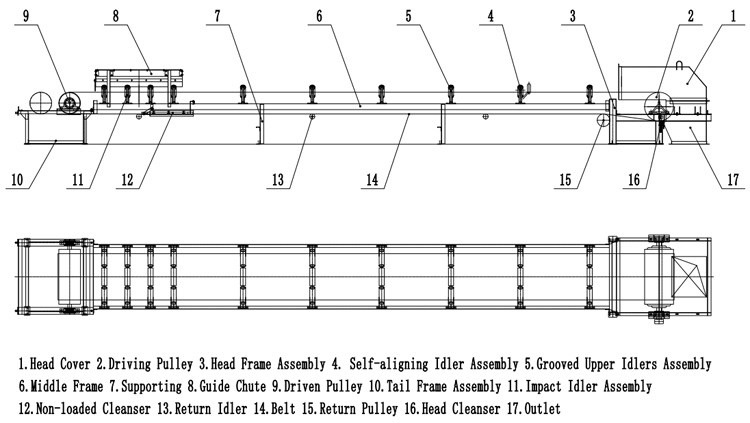

BELT CONVEYOR STRUCTURE

The main components of the belt conveyor are conveyor belt, idler and intermediate frame, pulley, driving device, tensioning device, brake device, cleaning device, protection device and unloading device.

ADVANTAGES

1. It can ransport many kinds of materials. All kinds of bulk materials, light weight products such as: cartons and packaging bags.

2. Optional moving selection of belt velocity (0.8m/s~4.0m/s). Work stably with less belt deviation and materials spillage.

3. Conveying stably, no relative movement between the material and the conveyor belt, to prevent damage to the conveying material.

4. Compared with other conveyors, it has less noise and is suitable for occasions where the working environment is relatively quiet.

SELECTION INSTRUCTIONS

Material to be processed:______ Handling capacity: ______ t/h

Bulk Density:______ t/m3 Center distance between the head and tail pulley:______ m

Material temperature:______ ℃ Working environment temperature: ______ ℃

Material is corrosive or not: ______ (Ps. Yes or No)

Water content:______ % Working environment: indoor? outdoor? ______

Max. granule size of the feeding material:______ mm Max. Granule’s percentage in whole material:______ %

The belt conveyor is inclined or not:______ (Ps. Yes or No) If it is inclined, what is the inclined degree______ °

Upstream equipment (using for feed the material):______

Downstream equipment (using for discharge the material):______

Whether needing supporting equipment?______ (Ps. Yes or No)

Working power supply: ______ V ______ HZ Quantity:______

The layout drawing : We will appreciate if you can provide us the layout drawing. The more detailed the better, because it can help our engineers to analyze, then we can give you the exactly quotation, supply the advanced technology support and more effective overseas installation and maintenance services.

Products

Products

Inquiry

Inquiry

WhatsApp

WhatsApp

Top

Top