Belt conveyor widely used for conveying bulk or granular materials, also to transport packed items. It is one of the most common continuous conveying equipment and economical conveyors. The belt conveyor can be used in the case of small transport capacity and short distances, and can transport materials over long distances with large transport capacity.

In order to keep belt conveyor running normally and have a longer service life, We should pay attention to its maintenance during the using process.

Today, YingDa Heavy Industry will share some skills about how to maintenance and servicing when using a belt conveyor.

׀. Pre-operation inspection

1. Check the reducer oil level, whether the oil quality is normal.

2. Check whether the inner roller and the tail roller of the belt are material sticking. If there is any material on the ground that prevents the belt from running, it should be cleaned up in time.

3. Confirm that the cleaner is adjusted to the proper position.

4. Confirm the roller quantity is right and working flexible.

5. Confirm the belt has no cracks, worn-out, and deviation.

6. Confirm there is no foreign matter in the inlet and outlet, suitable tensioning.

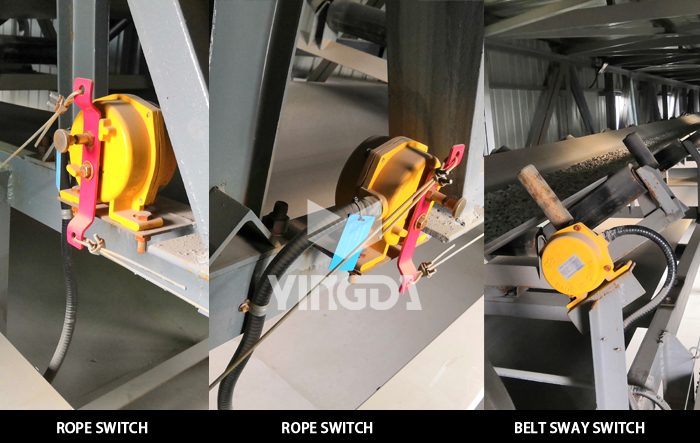

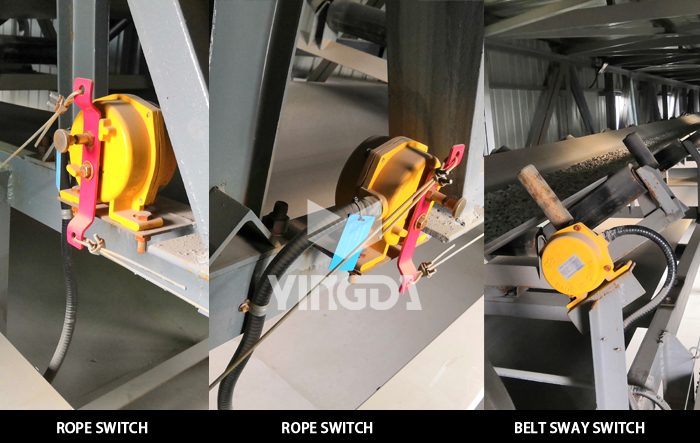

7. Confirm the rope switch is flexible and can be reset.

8. Make sure anchor bolts are fastening.

9. Whether the blanking baffle needs to be replaced or not.

Ⅱ. In-operation inspection

1. Confirm the conveying material is correct.

2. Confirm discharging evenly and the inlet and outlet are not accumulated. Prevent metal foreign matter stuck in the inlet and outlet so that to prevent damage to the belt.

3. Check if the reducer (motorized drum) has oil leakage or oil leakage, and it should be added in time when lack of oil.

4. Check each operating part for abnormal sound, vibration, temperature, and odor.

5. Whether the belt has a deviation or not, adjusted in time.

6. Whether the belt and belt joint is damaged or scratched.

7. Make sure belt cleaner working properly.

8. Whether the rotation of the roller and guide wheel is flexible.

9. Check the belt wear condition.

Ⅲ. Maintenance

1. Regularly replenish and replace lubricants and greases at various lubrication points.

2. Keep the rollers and pulley cleaning and flexible.

3. Timely replace rollers with inflexible rotation and severe wear.

4. Repair damaged inlet and outlet hoppers in time, adjust the cleaner in time to ensure cleaning effect.

5. Timely adjust tensioning device and rope switch, keep using flexible.

6. Whether the belt and belt joint is damaged or scratched.

7. Fastening loosing anchor bolts and replace worn-out sidewall belt.

YingDa Heavy Industry mainly manufactures belt conveyor, screw conveyor, bucket elevator, scraper conveyor and apron feeder, If you have any inquiry or interest, please feel free to contact us. www.ying-da.com

Further more belt conveyor maintenance skills, please email: info@ying-da.com

Products

Products

Inquiry

Inquiry

WhatsApp

WhatsApp

Top

Top